Cutting-edge analysis tools.

Oilgear engineers apply their expertise in CFD and FEA to ensure that Oilgear products and systems meet the demands of your application. This rigorous approach results in designs that are optimized for both performance and cost.

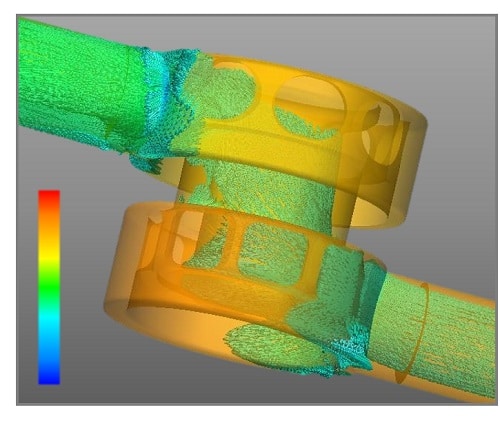

Oilgear employs computational fluid dynamics (CFD) to analyze the detailed effects of fluid flow in hydraulic control products and systems. CFD analysis can shed light on design issues such as flow restrictions, cavitation, erosion, flow transients, and flow forces.

Oilgear has both the Autodesk and Ansys CFD software packages so that we can adapt to the needs of our customers.

STRUCTURAL ANALYSIS

Oilgear uses finite element analysis (FEA) to investigate and optimize structural components of hydraulic products and systems. FEA is a powerful tool in guiding material selection and for improving weight and packaging.

As with CFD, Oilgear has both the Autodesk and Ansys FEA software packages so that we can adapt to the needs of our customers.

APPLICATIONS

Oilgear leverages CFD and FEA for Oilgear-internal projects and also offers CFD and FEA as a service. Some recent applications include:

CFD

Optimization of flow efficiency for subsea BOP control valve

Optimization of pump valve port to minimize cavitation

Gas emergency shutoff valve analysis

Optimization of high-speed relief valve for rock crusher application

Design of next generation subsea pressure regulator

FEA

Weight optimization of subsea ROV manifold

Material selection for axial-piston, variable-displacement pump

Design of locking mechanism for offshore drillstring and landing string inline compensator

Material selection for 2-position 3-way control valve

Weight optimization of air pressure vessel (APV)