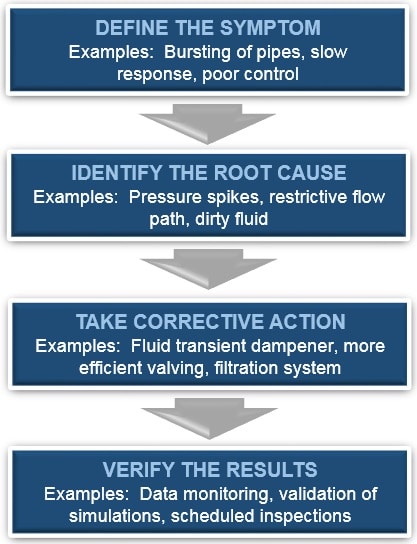

Define. Analyze. Prevent.

Oilgear’s Root Cause Analysis Team is focused on getting to the heart of your complex hydraulic problems. Our world-class engineers draw from the most modern tool set that technology has to offer.

THE OILGEAR RCA

Root cause analysis (RCA) is a systematic approach to problem solving used for identifying the underlying causes of problems or faults. A factor is deemed a root cause if, by its removal or rectification, the unwanted end-result no longer occurs.

The Oilgear RCA Team consists of our best and brightest hydraulic and electrical control engineers and focuses on solving our partner’s problems as quickly and efficiently as possible. Whether you require support for an RCA, FMEA, or FMECA, onshore, offshore, or subsea, the Oilgear team is here to help.

HYDRAULIC EXPERTS WITH A SYSTEMATIC APPROACH

The key to any successful root cause analysis is to combine industry specialists with a systematic, methodical approach to problem solving. Oilgear’s hydraulic and electrical control experts embed with your application team to ensure that all relevant input is considered during the analysis process.

Some examples of application where Oilgear’s RCA Team has had success include:

- Forging press control

- BOP ram actuation timing

- Extrusion press efficiency optimization

- Pressure spikes in rock crusher relief system

- Third-party analysis of failure modes of hydraulic components

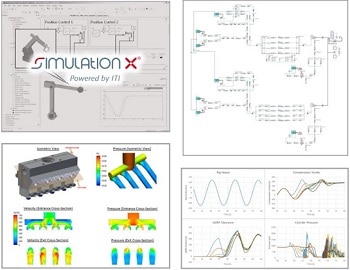

SIMULATION, TESTING, ENGINEERED SOLUTIONS

Oilgear offers a one-stop-shop for analysis, testing, and engineered solutions. Our full suite of hydraulic control simulation and design tools includes:

- SimulationX multi-physics simulation software

- Proprietary Oilgear simulation coding for analyzing fluid transients (i.e. water hammer and decompression pulses)

- Over a dozen hydraulic test stands, including flow test stands, pump test stands, and valve fatigue cycle test stands

- Complete design, machining, and assembly capabilities